If you're working on serious projects there are often serious risks. A lot of these can be mitigated by preventative measures and safety gear but ultimately some fallout is expected. This is a compilation of various lab accidents I've been involved with, what caused them, and the outcome. I've placed them roughly in order of increasing risk and/or actual injuries. Of all of these, only a few resulted in any injuries at all.

I'm focusing on unintentional explosions or at least things that had unintended consequences. There are also many things I've done that *could* have ended badly but didn't...leaving those off for now. I'll update this list as things evolve and announce updates to Twitter.

Honorable mentions

Intentional or very minor incidents. I'll save these for separate posts.

Miswired SCR

I

had a Trygon power supply from a garage sale:

It got used for various tests as benchtop power supplies tend to.

I need to actuate the SCRs (high power switch) on my 400 V capacitor bank. This power supply, along with a filter capacitor, provided sufficient current. The test completed and everything was working fine.

As I cleaned up there was some interest to see a demo. I then hastily hooked it back up and miswired the power supply to the wrong SCR terminal, putting 400 V into it. This released profuse magic smoke and severely damaged the power supply.

Damage:

- Blew up power supply

- Street cred

Lessons:

- Double check wiring, especially on high power systems

- Do a final dry run before a live demo (ask them to come back)

Circa 2005

Pyrex custard cup

I've been experimenting with ways to decap metal-epoxy chips like Xilinx Virtex dice. One way is to heat it to soften the epoxy and allow removing the metal cap:

Ultimately I did this with a hotplate but early tests used a torch.

I used a Pyrex custard cup to hold the die during torching. These are heat resistant and so figured it would probably be okay. And it more or less was as I completed the work without incident.

However, some months pass and I re-use the custard cup to insulate some molten solder:

I dropped something in the custard cup and went to gently pick it up with tweezers. This light touch was sufficient to explosively shatter the dish:

I found pieces a few feet away. I'm guessing after torching the glass cooled unevenly, putting it under high stress. The heatgun somehow exacerbated that and pushed it over the edge.

Fortunately the solder beaker didn't tip over.

Damage:

- Broken custard cup

- Increased risk: spill molten solder

Takeaways:

- Equipment history can be important

- Safety gear did its job

2015-12-19

Mica implosion

Someone gave me a pile of photomultiplier tubes (PMTs) along with some alpha window GM tubes. Mica is often used in alpha detectors as it passes most alpha particles, is strong, and is vacuum tight.

The PMTs had black covers to protect optical surfaces before use. Naturally I peeled that off before use. Similarly, when I picked up the mica window GM tube I attempted to remove the "cover" before use. Some background...

This is what raw mica looks like:

However, my tube looked like this:

As I tried to remove the "cover" with tweezers it imploded in my face and left this:

Damage:

- Broken sensor

- Increased risk: eyes

Takeaways:

- "Harmless" operations may warrant safety glasses

Circa 2015

Shouldn't be standing here

I occasionally use a cylotron's proton beam to qualify satellite electronics. One of its many safety features is a (lead?) block that absorbs unused protons. When workers need to enter the experiment chamber the block recedes into a box that then latches. There is also a radiation monitor next to the chamber door to verify its safe to enter.

One time I checked the radiation monitor and verified it was safe to enter. I then slid the several ton chamber door open and headed inside. However, I was started as the beam stop was still up. Thoughts going through my head:

- Is the proton beam armed?

- Is that block emitting hazardous ionizing radiation?

I immediately exited the area and it shortly thereafter receded into its box. Fortunately there are many layers of safety (ex: interlocks on the door, radiation monitoring) and I wasn't under any danger.

Damage:

Takeaways:

- Always check CCTV before entering

Circa 2014

Rosin decap

One way to decapsulate (open up / "decap") an IC is to use hot abietic acid as found in rosin

I wanted to try this but the hotplate was busy. So I instead made a makeshift alcohol lamp.

I didn't run this for very long before the test tube cracked (uneven flame?) and the mess caught fire. Fortunately the fire was small, contained to the metal plate, and easily extinguished.

Every time I tried rosin decap it ended badly. It was eventually abandoned in favor of superior nitric and sulfuric acid decap processes.

Damage:

- Small fire

- Broken test tube

- Increased risk: broken mercury thermometer

- Increased risk: larger fire

Takeaways:

- Wait for proper equipment

Circa 2005

400V capacitor bank bringup

I love capacitors and easily have a half ton of them. Mostly I blow stuff up but I'm starting to branch out into more constructive uses. Anyway...

350 - 450 V range capacitors are great because you can raid inverters for low ESR/ESL versions.

For example, a Toyota Prius inverter has three such capacitors with beefy terminals.

Even still, I was on a shoestring budget and had to use what came my way. I started by getting copper sheets from a local metal shop. I then used tin snips to cut it up but it came out pretty rough. I thought about carefully filing everything down but decided on a more practical approach: let the shorts blow themselves out. So for the first bit of operation it would occasionally BANG as the splinters shorted across the high power 400 V rails. And it seemed to work but I eventually also filed it down.

But this post is about the unplanned bits. I kept costs low by buying well used capacitors from

Jason Rollette. These were capacitors that were probably okay but he didn't want to risk exploding. And you don't want soda can sized capacitors exploding.

So I sort of had this coming. After some operation I heard a large bang even though I hadn't fired the switch. After an inspection found nothing, I dismissed it as a temporary short from metal shavings. But it happened again and at that point I had to acknowledge there was a problem. I inspected everything once more and didn't see any damage.

Without any leads it was time for a full rebuild. I then got a nasty surprise: as a rail was unbolted one of its capacitors fell apart!

The root failure seems to be that the aluminum plates slid down. Eventually they slid off the insulator and shorted.

The power bus bars held the failed unit firmly in place. When the capacitor failed the bus bars gave way enough to vent gas but immediately clamped the capacitor back shut.

Damage:

- Broken capacitor

- Increased risk: shrapnel

Takeaways:

- When you buy sketchy equipment be ready for the consequences

- Even severe damage can be hard to see

Circa 2006

Hotplate meltdown

I originally decapped most chips with sulfuric acid because its easier to get than nitric acid. However, if hot sulfuric acid concentration drops too low it can foam up...possibly overflowing quite badly.

I was doing a large batch of chips (SecurIDs maybe?) in a 1 L beaker. It got too hot, not enough acid, etc, and overflowed.

The mess billowed awful smelling smoke and began eating my hot plate, removing most of the paint. Fortunately I keep a large amount of baking soda ready and carpet bombed the area. Despite cleanup, electrical corrosion ultimately required me to replace the hotplate.

Damage:

- Hotplate, ultimately causing failure

- Sample put at risk

- Acid spill

Takeaways:

- Watch large chemical batches carefully

- Being ready for a large spill was a good idea

Circa 2012

Careless gunpowder storage

I had made some gunpowder and had some sitting on an outside table. I was experimenting with fuse design and was burning a fuse 6 feet or so away. A spark managed to land on the gunpowder pile and ignite it. While it didn't burn the table, in surprise I jumped back and knocked over an graduated cylinder, breaking it on the concrete below.

Damage:

- Broken glassware

- (Larger) fire risk

- Wasted gunpowder

Takeaways:

- Store unused explosives better

- Keep test area clear

Circa 2005

Thermometer handyman

Sometimes alcohol thermometers get bubbles in them which destroys the accuracy. Unusually the best way to fix this is to cool it so that the alcohol completely recedes to the bottom reservoir. Then its slowly warmed such that all the air is forced out first before the alcohol fills the column. Alternatively, you can theoretically force out all the bubbles to the top and slowly cool it in a similar manner.

So I tried cooling it in a -100 C alcohol bath. Unfortunately that was not cold enough to make it fully recede.

I decided I had nothing to loose at that point an decided to heat it. I can't recall if I used a torch or a heatgun. What I do recall though is there was no flame on it when it finally gave way. The alcohol had been heated sufficiently though that when it glass broke it spontaneously combusted with the air, sending glass shrapnel about. Once again, due to wearing safety equipment no injuries were sustained.

Damage:

Takeaways:

- Should have explored more options

- Safety gear did its job

Circa 2010

Red gas

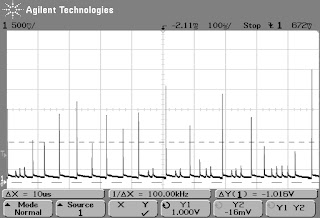

Above: NO2 during RFNA distillation

In AP chemistry, a student asked the teacher if you should breath NO2. He said he wasn't sure, but, based on the color, doesn't recommend it. And he's right: it would turn into a mix of nitric and nitrous acid in your lungs if inhaled. Similarly, like nitric acid, it yellows and dries out skin on contact.

Enough background. Sulfuric acid with a nitrate group (KNO3 or HNO3) can be used to nitrate cellulose to make nitrocellulose for uh...DIY ping pong balls. Yeah that's it. Anyway, the reaction gives off a lot of heat and needs to be cooled to prevent thermal runaway (more heat => faster reaction => more heat). The heat also causes the nitrate groups to decompose, releasing NO2.

One time this happened and I (for whatever poorly judged reason) decided to plug the bottle with my finger. Maybe I was hoping the problem would go away if I ignored it? Of course, I mean with my bare finger as I didn't have the budget for gloves and such. After a bit I let go and ran away to let things cool off. The NO2 left an orange circle on my finger that healed up within a few weeks.

Above: minor nitric acid exposure healing (produces similar burns). Less extreme version of this incident

I also recall seeing a red plume of gas shooting out of my work area. Wonder if any neighbors saw that?

Damage:

- Dried out, discolored skin

- Probably some repository exposure

- Increased risk: explosion

Takeaways:

- Wear gloves and respiratory protection

- Cool exothermic reactions

Circa 2005

Nitric acid storage

Originally I made my own nitric acid and refined a

streamlined process for it. Here's a photo before I added cryocooling:

But its still a lot of work. For a short period people sold white fuming nitric acid (WFNA) on eBay. So I bought a bunch from a seller that probably used a similar process (I could see crystalline impurities).

The bottles also had other quality issues like poorly affixed low quality labels. They taped the lids closed (good practice) but didn't bag anything or even put snug packaging when shipped. Obviously not labeled as a hazardous shipment either. While that was an accident waiting to happen, it hadn't caused any trouble.

I had previously stored Red Fuming Nitric Acid (RFNA) in similar bottles and discovered that the NO2 fumes eat through the lids (above). However WFNA seemed to be fine so I didn't put much thought into it. Three of the four 125 mL bottles were stored away in my acid storage cabinet (gutted microwave) while one was left out on the counter for general use.

One day I came out to find an exploded bottle. Shards were scattered across the table along with some acid. Fortunately, the bottle rested in a large custard cup that was damaged by the explosion but still contained most of the acid.

How did this happen? The bottle stored outside was heated up by the hot days. This caused HNO3 to decompose, building up NO2. Eventually pressure buildup caused the bottle to burst. Bottles in the cabinet stayed cooler and, while they were pressurized, hadn't reached dangerous levels. Not knowing if they were ready to explode, opening them was a bit stressful but occurred without incident.

The acid was repackaged into larger half full FEP (plastic) bottles so that it had lots of room for gas release and would hopefully not break as easily. All acid is now stored in a cool area when not in use.

Damage:

- Broken glassware

- Table corrosion

- Increased risk: fire from uncontrolled acid reactions

Takeaways:

- Store reactive chemicals properly

Circa 2013

80,000 V death capacitor

Items bear warnings like "may cause injury", "may cause death", etc. However, this capacitor has no hedging: if you get shocked (when fully charged) you will die.

The capacitor has bleeder resistors to discharge to a safe level IIRC in a few minutes (a compromise between safety and high losses). After firing I switch off and disconnect the high voltage power supply. I then short / discharge the capacitor with a conductor on a stick. Finally, I wrap a wire around the capacitor terminals.

Despite discharge, capacitors can slightly charge back up. On small capacitors this tends to be negligible but ones this size give an uncomfortable shock.

I was doing a demo at Maker's Faire and had just used the shorting stick. Rushing to get the next demo ready, I hastily wrapped the shorting wire around the terminals. Usually I'm careful not to touch the terminals but my hand brushed against them and delivered a nasty shock. Low power and unharmed, I kept working and proceeded with the demo.

Damage:

- Temporary discomfort

- Increased risk: lethal shock

Takeaways:

- Wear insulating gloves

- Add automatic/remote short system

Circa 2015

H2SO4 storage

Above: incident area in 2015

I bought some H2SO4 and used most of it immediately. Unfortunately the original plastic bottle didn't fit in my cabinet. So I transferred the contents to a couple of small plastic bottles. Finally, the cabinet was temporarily blocked so I decided to temporarily store them on a shelf next to my bed.

The next morning I discovered acid melted through one of the bottles. It then etched the shelf, took out some of the nearby wall, and melted a book on the floor.

Oops.

But it could have been much worse: imagine if the bottle splashed towards me sleeping, waking me to a concentrated sulfuric acid bath.

Above: the wall after painting

Damage:

- Melted shelf a bit

- Melted wall a bit

- Destroyed book

- Lost acid

Takeaways:

- Don't store strong chemicals in your bedroom

- Not all plastics are created equal

Circa 2005

There used to be carpet there

Of course I didn't just melt the wall. Fuzzy on the timeline, but above and this occurred at roughly the same time. I may have given my parents an ulcer or two.

I had a few hundred mL of acetone and H2SO4 waste stored in a glass peanut butter jar. At the time I didn't have an outside workspace and wasn't sure how to dispose of it.

One day as I added more more waste it tipped over, immediately melting my carpet.

To make it not look quite so bad to my parents, I used scissors to grab bits of carpet from other areas in the room and glued it on. On the bright side, the very old carpet was finally replaced (with more durable Pergo) and I got an outside workspace.

Above: after the floor was replaced. Chemicals were stored in the wood cabinet and spilled in front of the door.

Damage:

- Foot wide area of missing carpet

Takeaways:

- Don't store powerful solvents in your bedroom

Circa 2005

Hot lead and water

If you've ever cast bullets you've probably been warned about this.

Above: gamma spectroscopy lead ingot castle

Its best to take a gamma spectrum without background radiation. One easy way to do this is to stack lead bricks around the detector and sample. Crude ingots work okay but don't seal well, slightly degrading the signal.

So I CNC'd some lead brick molds and successfully poured some bricks. However, to accelerate cooling I would dunk molds in water. I would dry out the molds before re-pouring such as the mold being preheated above. This is important as any water trapped in hot lead gets superheated and causes a molten lead explosion.

Scrap lead is recycled back to the pot. One of the pieces evidently got splashed, trapping lots of water. When it was thrown into the 20 lb lead pot, a large explosion sent most of the molten lead flying. Some of it fused into plastic boxes a few feet away as well as onto my protective gear. Had I not been wearing a full faceplate respirator I would have been blinded.

Damage:

- Minor equipment damage

- Big mess

- Increased risk: blindness, burns

Takeaways:

- Only throw dry lead into the pot

- Safety gear did its job

Circa 2014

Burning man

The only time I thoroughly caught myself on fire.

There's a fun party trick where you cover your hand in a volatile flammable substance (ie alcohol) and light it. Until the flame burns down it won't burn you. I've intentionally lit my hand on fire this way without incident.

And now things escalate. I was scavenging with some college chums and we found a bottle of pure medical grade ethanol. Most college students would probably drink it, but we just put it on the shelf.

One day I was bored and came up with a "good" idea. You see, I always wanted to make a Molotov cocktail and this seemed like the perfect opportunity. Indoors of course; doing this outside would attract too much attention. I grabbed a chemistry flask and partially filled it with alcohol. Next I stuffed paper towels in as a pilot light. Finally I lit it and immediately things went very wrong.

Turns out that ethanol burns really well. Well enough, for example, that its used as racecar fuel. When I lit the towel the ethanol in the flask exploded, covering my left arm and left leg with flaming alcohol. Surprised, I dropped the flask on the floor, lighting it on fire.

I realized I wasn't in any immediate danger, remembering my previous hand lighting trick. I quickly patted myself out and stomped out the floor. Other than a few singed hairs on my arm, neither myself, my clothes, nor the floor received any damage.

Damage:

- Increased (larger) fire risk

- Risk of burns

Takeaways:

- If you are going to do something stupid, film it

- Think twice before "stop, drop, and roll" as the floor may be on fire

- Party tricks are a survival skill

Circa 2009

Sulfuric acid burn

As I washed out sulfuric acid coated beakers a drop fell onto my

hand. I immediately washed it off with the hose which, in

foresight, may have actually been a bad idea. The water momentarily

superheated the acid and may have actually made it worse. I would have

been better off quickly wiping it off and then rinsing with water.

The

acid left a large burn where the drop hit as well as a small streak of skin where the drop rolled off my hand.

Damage:

Takeaways:

- Wear gloves

- "Empty" glassware poses risks just like full glassware

- Spray beakers with water before handling

Circa 2005

Soldering iron burn

I'm no stranger to soldering iron burns but there is one incident that stands out.

When most people think about soldering irons, they think of something like my WES51. But that's not the type of soldering iron I'm talking about.

My dad has a high power pipe soldering iron. IIRC I was soldering air ducts for my Tesla coil. At some point my left hand accidentally touched the base, turning the skin to ash (third degree burn). I still have a small scar.

Damage:

- Small third degree burn giving scar

Takeaways:

- Mind the whole tool, not just the tip

- Use gloves

Circa 2002

Shell shocked

The only time I've been paralyzed by an explosion.

Hydrogen

gas is fun to play with and is easy to get by using

electrolysis to split water. To that end, I took a plastic grape juice

bottle and drilled holes in the lid for carbon electrodes. I also fitted an electric solenoid to release gas.

The

machine was setup on the side of the house, a semi-enclosed area.

Usually my brother is smart enough to stay away when I do stuff like

this but decided to tag along today.

I actuated the

solenoid and lit the output gas to get a satisfying flame jet. For

some reason I decided to change the nozzle. However, it no longer worked smoothly: the hydrogen was

stuttering and extinguishing. I tried this a few times and then got a

nasty surprise.

Of course, it wasn't just hydrogen in

the tank but a perfect mix of hydrogen and oxygen. By chance, the first nozzle kept pressure such that the flame couldn't flash back into the tank.

However, the second nozzle didn't and the flame

flashed into the bottle next to us, exploding in the semi-enclosed

area.

The blast numbed me and all the dogs in the

neighborhood were barking. A few seconds later my mom, who was in the

kitchen not too far away, went to the window and asked if that was a

hydrogen balloon popping. She knew I was playing with hydrogen and earlier I mentioned hydrogen balloons pop

louder than other gases. My mind barely working, I muttered out a "yes"

and she left and went back to the kitchen.

Slightly wet and possibly some hearing lost, we were otherwise unharmed.

Damage:

- Hearing damage?

- Increased risk: shrapnel

- Increased risk: fire

Takeaways:

- Lighting a tank of mixed hydrogen and oxygen is a bad idea

- Think carefully when things aren't working

- Light remotely

- Work in an open, flame resistant area

Circa 2005

Hydrofluoric acid burn

Yes

that's right, this isn't number 1. Stay tuned for more fun. In part

its because I'm actually not entirely sure that this was an HF burn, but

its my best guess as to what happened.

I use HF to delayer integrated circuits for

photos like this.

Don't be fooled by Breaking Bad: concentrated HF is extremely toxic. Any skin contact and/or inhaled fumes can have dire consequences.

Fortunately, I didn't start using HF until later in my chemistry

"career" such that I had developed a lot more safety sense and funding

to purchase safety supplies. For example, when handling 48% HF I wear a

full hazmat suite and keep calcium gluconate around.

I

believe for the incident in question I was using 12% HF. A few days

after the work I had a sore area on my right shin. This wasn't so

unexpected though because a bicycle chain had rubbed against there and

tore up my leg a little. Didn't think much of it at the time.

However,

weeks passed and it didn't entirely heal up. One area was slow to heal

and two areas didn't heal. For months it would slowly heal but the

skin was unusually weak and could basically just be rubbed off.

I

don't recall exactly at what point but at some time I suspected it

could be (minor necrosis?) from an HF burn and rubbed some calcium gluconate on

it. I'm unclear if this helped but it did eventually

heal.

My theory: some dilute HF spilled (during

cleanup?) and fell on the ground. This splashed upwards past my

socks and under my pants to land high on my shin. Maybe usually this

would not have caused a burn but my exposed wounds made me more

vulnerable.

Damage:

- Minor skin damage

- Long term health concerns

Takeaways:

- Use extreme caution when handling dangerous chemicals

- While face and hand

protection is important, don't skimp on other areas of the body that you

might think are low risk

Circa 2013

Chlorine gas explosion

I wanted some hydrochloric acid to play with for chemistry experiments but the local hardware store wouldn't sell me any (muriatic acid) because I was under age. So I thought, what alternative sources could I find?

I went to the local dollar store and scoured cheap cleaner ingredients lists. After some rummaging I found some toilet bowl cleaner that was basically colored HCl. I brought it home and it seemed to work: I could dissolve zinc and what not to my hearts content. But it wasn't very pure or strong...what could I do to improve that?

Next I bought some table salt (NaCl) and added it to the toilet bowl cleaner. This forced HCl gas out which I then bubbled through some water to get a small quantity of pure, concentrated hydrochloric acid.

But hmm...its going to be slow and expensive to make any real quantity. How could I scale up?

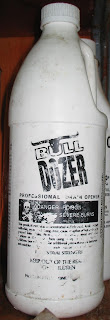

While the hardware store wouldn't sell me muriatic acid, they sold me Bull Dozer brand drain cleaner (98% H2SO4) along with solid calcium hypochlorite (pool bleach). And, yes, this is the same bottle that melted the wall and carpet. Anyway, these two chemicals can be mixed to produce copious amounts of chlorine gas (a highly corrosive war agent). Similarly, copious amounts of hydrogen can be produced by reacting aluminum metal with lye solution.

These reactions took place in two side arm flasks. Hoses coupled evolved gases into a tee junction that fed the produced hydrogen chloride into a third flask to bubble it through water to produce hydrochloric acid.

So an explosive gas and a WW I war gas...what could go wrong?

I started each reaction and the system only ran for a few seconds before the heat in the T junction caused it to spontaneously combust. This means the hydrogen reached 536 °C / 997 °F.

Now one flask is spewing poison gas and the other has a one foot flame jet. Once again, safety equipment was too expensive so no respirator/gloves but I may have had goggles.

I uncapped the hydrogen flask which flashed and went out. I then diluted the chlorine flask to slow down the reaction. With both flasks under control I exited the area.

While I wasn't there for very long that short exposure gave me minor difficulty breathing for about a week and a wheeze for about 6 months. This makes it the only accident that gave me significant injury. Fortunately today I seem to be fully recovered.

Damage:

- Minor difficulty breathing for 1 week

- Wheeze for 6 months

Takeaways:

- Use safety gear (respirators, gloves, etc)

- You should just let kids buy chemicals...its for their own good

Circa 2004

That's all folks

Hope you enjoyed. If you want more experimental madness check out Derek Lowe's excellent "

Things I Won't Work With".